Panel Bender Machines

Panel Bender Machines

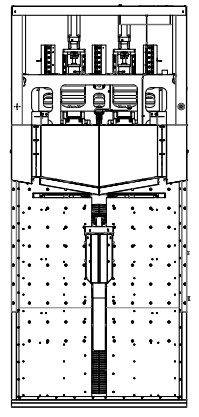

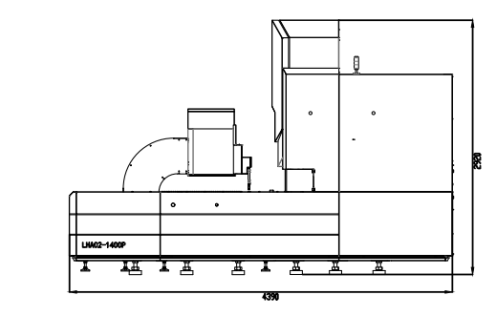

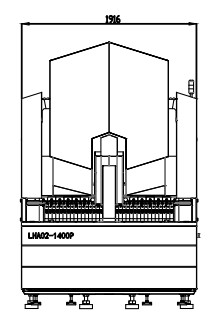

1、Equipment picture

1.1.Equipment outlook

1.2.Equipment outlook structure diagram

2、Equipment overview

2.1.Functional profile

Industry 4.0 architecture, which can be upgraded smoothly;

Fast speed, only need 0.2 seconds per knife;

Fast molding of the workpiece, high consistency;

Low power consumption;

Simple daily maintenance and low cost;

High degree of automation, simple operation, low requirements for labor;

No need to mold, complex shape (folded or folded right Angle, non-right Angle, etc.) arbitrary design at any time production;

Suitable for a wide range of materials, mainly stainless steel, cold-rolled plate, etc.;

Compatible with all kinds of loading and unloading methods: manual loading and unloading, self-drive arm loading and unloading, butt arm loading and unloading are optional;

The intelligent bend center has rich software and hardware interfaces, which lays a good foundation for the intelligent factory;

The control system realizes the 15-axis + concurrent linkage in the true sense, with smooth bending action and high coordination of mechanical operation;

The partial load detection system can effectively protect the machine protection workpiece;

Plate thickness detection system can effectively protect the machine and reduce the waste of the workpiece;

Cloud operation and maintenance management system can monitor the operation of the machine in real time, and can conduct comprehensive customized management of the company’s business;

Human-machine interface is friendly, easy to understand, flexible programming;

For the workpiece with irregular size, different positioning benchmarks can be selected according to the shape of the workpiece, and the shear error of the plate can be controlled at the edge of the first bend to ensure the accuracy of the size after forming.

3、Technical parameter

| Technical parameter | |

| Material delivery structure | Pressure arm type |

| Workbench structure | hairbrush |

| System minimum accuracy | 0.001mm |

| The fastest bending speed | 0.2 s/times 0.2s/knife |

| Maximum feeding speed | 90m/min |

| Maximum bending width | 1400mm |

| Maximum bending size | Length 1400mm X width1400mm |

| Maximum bend height | 170mm |

| Minimum bend height | 3mm |

| Minimum arc radius | 0.5mm |

| rated voltage | 380V |

| Total motor power | 40KW |

| mean power | Around 1.9KW |

| noise | Around 50 DB |

| outline dimension | around:length 440cm X width 190cm X height 290cm |

| gross wight | Around 15 Tons |

| User operation environment | above windows 7 |

| Maximum bending thickness | UTS 515N/mm2 304 SS 1.5mm UTS 410N/mm2 Cold rolled plate 3.0mm UTS 265N/mm2 Alu plate 3.0mm |

| Minimum material thickness | 0.35mm |

| Minimum inner size of quadrilateral | 140mmx190mm |

| Bilateral forming minimum internal size | 140mm |

| Bend Angle | 0-180 degree |

| number of axles | 15 |

4、Functional configuration

| main functional configuration | |

| high-grade casting frame | High grade QT 500-7 and grey iron 250 casting are used to effectively ensure the stability under high tonnage impact force |

| axis+ concurrent linkage control system | Standard support 128 axis, single control board support up to 32 axis concurrent linkage, can achieve infinite cascade; |

| advanced instruction | Users can customize the design and control of complex artifacts according to their needs, |

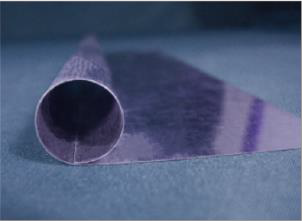

| arc instruction | Directly call the arc instruction, input the radius to achieve the bending of the arc |

| double Y axis lifting + U axis positioning by the ruler | Double Y-axis double lift ruler + U-axis ruler automatically clamp positioning, greatly improve the accuracy and consistency of the workpiece after forming |

| plate error detection | When the plate is used wrong, the system will automatically alarm, effectively avoid the damage to the machine due to the wrong size and type of the plate. |

| oil- supply self-lubrucation system | automatic alarm to ensure the safe operation of the machine |

| unbalanced loading detection system | When a foreign body or other situation causes the two sides of the press knife are not on the same level, the system alarms and stops the operation to effectively protect the mechanical structure. |

| double C axis automatically following | The upper and lower pressure claws automatically follow, and according to the shape of the workpiece, automatically switch the borrowing mode to realize the workpiece bending |

| plate depth detection system | The thickness of the workpiece is detected in real time during the press tool. When the actual thickness is inconsistent with the program thickness, the system immediately stops and alarms. |

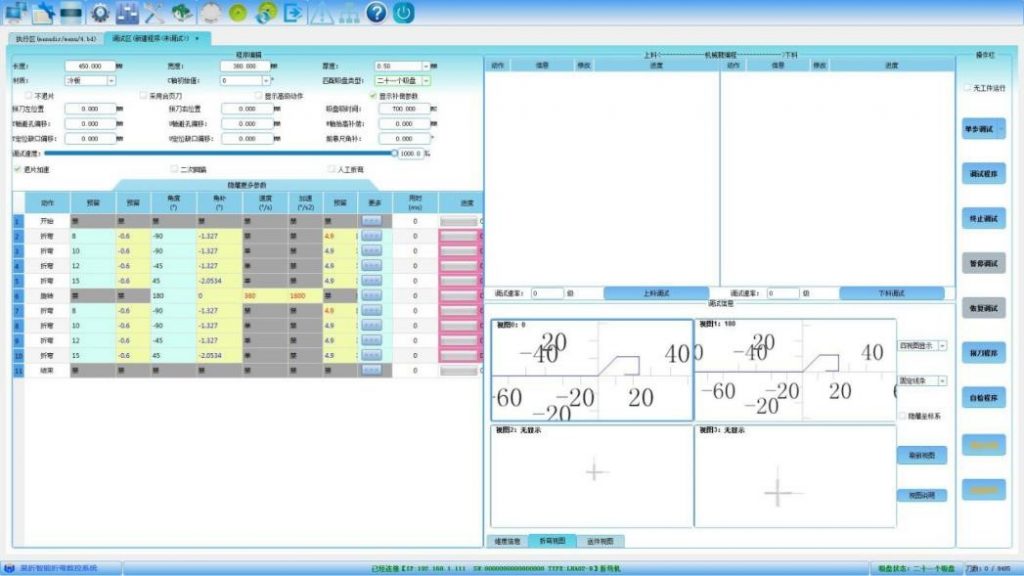

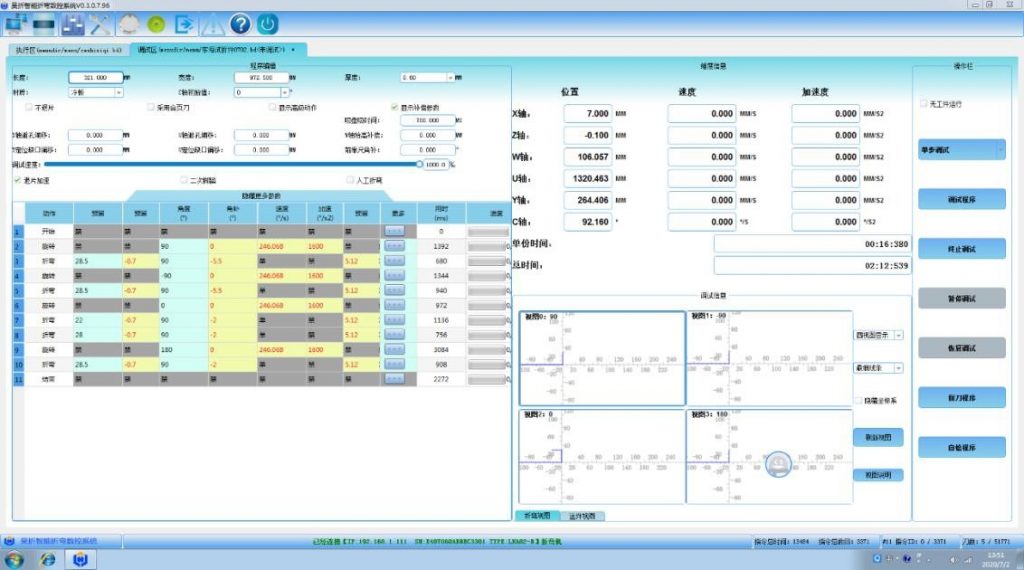

| diagram visualization detection programming | The user only needs to input the bending size and instructions, the system automatically completes the programming, and show the molding results, the user can make a comparison to ensure the consistency. |

| auto loading and unloading control module | The system reserves a rich industrial 4.0 interface, which can dock with the robotic arm to realize automatic loading and unloading. Select lanhao self- drive mechanical arm, which is the same control system as the bending center. Change the workpiece without secondary programming. The system automatically generates the mechanical arm action according to the bending command, with higher efficiency and better coordination. |

| high speed control module | The system can realize the cooperative work under the high-speed operation |

| flat function | Realize the pressure leveling of the workpiece |

| press up and down | Realize the workpiece up and down the dead edge |

| hand wheel | The system has the function of anti-collision knife, and the user can control each axis to any desired position through the hand wheel |

| could and operation maintenance management interface | It can connect with enterprise operation and maintenance management system, detect the operation of the machine in real time, and carry out all-round customized management of the company’s business |

| auto production line interface | It can connect with upstream and downstream production equipment to realize automatic production |

| C axis rotation strength | The C-axis rotation speed and accuracy are improved |

| easily install for upper pressing knife | Quick removal and quick installation replacement knife |

| Power combined page knife | Equipped with power blade, accurately control the lifting of the blade, effectively avoid shovel plate, scratch problems. |

5、Example

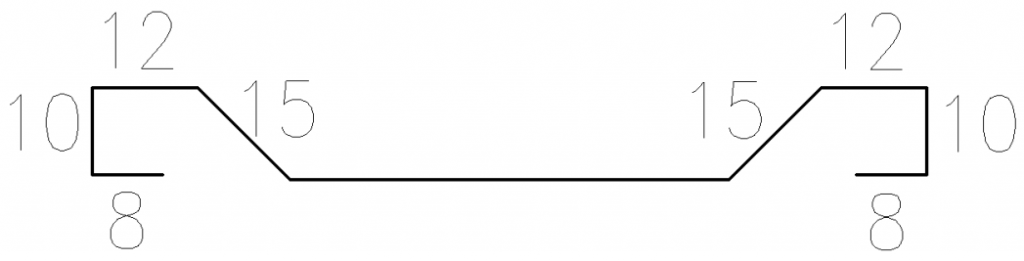

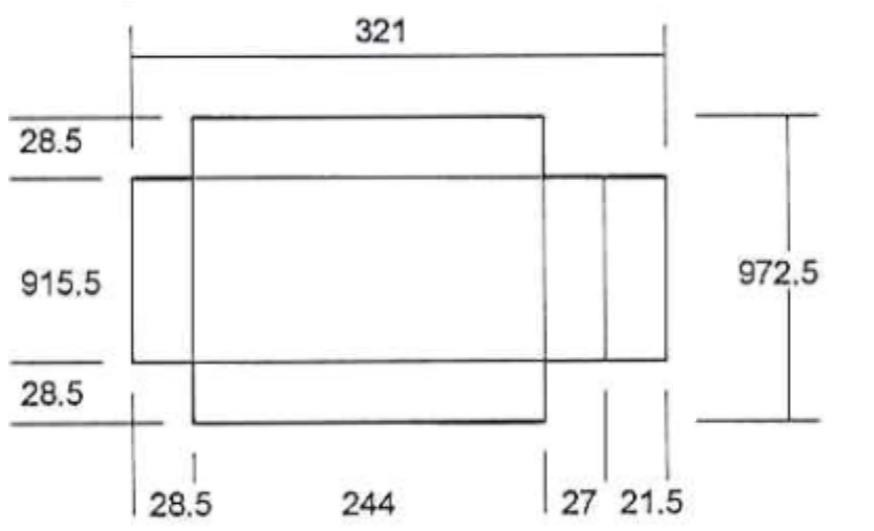

5.1.1.Drawing

5.1.2.Configuration

5.2.1.Drawing

5.2.2.Configuration

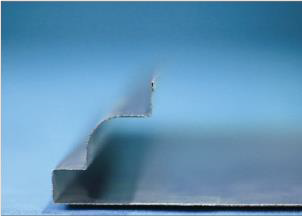

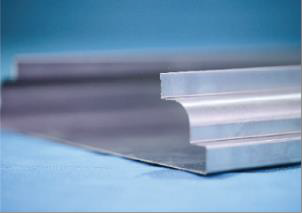

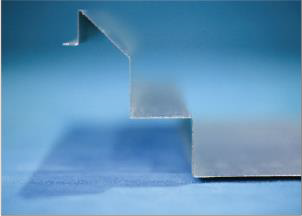

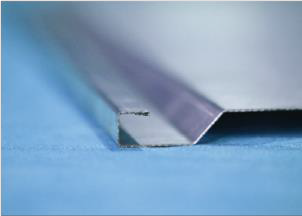

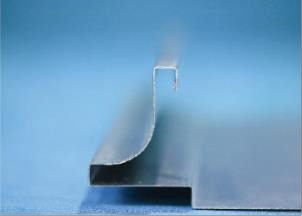

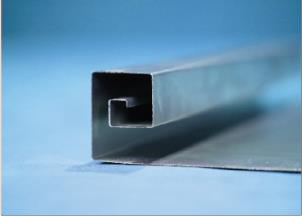

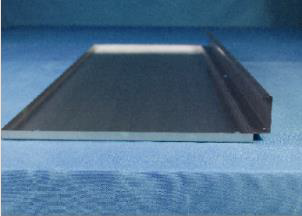

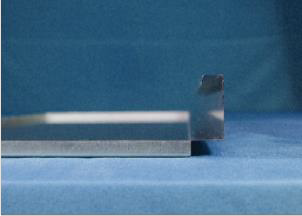

5.3.Formed parts example

About the author

Alvis Zhang of VISTMAC Machinery

VISTMAC is a professional manufacturer and exporter in tube processing machines, includes Pipe Bending Machines, Pipe Cutting Machines, Wire Bending Machines, and Pipe-End Forming Machines Series.

Let’s Talk

China CNC Pipe Bending Machine Manufacturer directly selling Pipe Bending Machine, Wire Bending Machine with CE marking at affordable price

© Copyright 2023. All rights reserved.

Phone/WeChat: +86-13771480707

Email: sales@chinasmartcnc.com

Address: Head Office: No.77 Huicheng Road, Huishan District, Wuxi, Jiangsu, 214151, ChinaWORKING DAYS/HOURS:Mon-Sat / 8:00 AM – 18:00 PM

About us

Machines

Showroom

Support

News

Contact us

Help & FAQ

News

Privacy Policy