Description

III.Main technical parameters

MODEL: C1-2500

| NO. | NAME | UNIT | PARAMETER |

| 1. | Feeding structure | / | Press arm type |

| 2. | Max. bending length | mm | 2500 |

| 3. | Max. bending height | mm | 170(optional 300) |

| 4. | Min. bending height | mm | 4 |

| 5. | Min. molding size of four sides | mm | 330*330 |

| 6. | Min. molding size of one side | mm | 200 |

| 7. | Min. arc radius | mm | 1.2 |

| 8. | Min. continuous bending speed | S | 0.2 |

| 9. | Bending angle | Degree | 0-180 |

| 10. | Number of control axes | 10 (most up to 15) | |

| 11. | Max. feeding speed | m/min | 120 |

| 12. | Dimension | mm | 6200*4300*2500 |

| 13. | Total power | KW | 43/45 |

| 14. | Average power | KW | 2 |

| 15. | Working table structure | / | Brush |

| 16. | Speed adjustment | Standard | |

| 17. | Advanced instructions | Standard | |

| 18. | Arc instructions | Standard | |

| 19. | Crushed edge instructions | Standard | |

| 20. | Loading robot interface | Standard | |

| 21. | Hinge knife | Optional |

IV.Main components configurations list

| NO. | NAME | BRAND | ORIGIN |

| 1 | System control unit | SMART CNC | China |

| 2 | Servo unit | Designated R&D | Joint venture |

| 3 | Linear guides | Rexroth | Germany |

| 4 | Ball screw | HIWIN | Taiwan, China |

| 5 | Main electrical components | Schneider | France |

| 6 | Pneumatic components | SMART CNC | Taiwan, China |

| 7 | Bearing | NSK | Japan |

| 8 | Reducer | Designated R&D | China |

| 9 | Bending machine body | SMART CNC | China |

V.Bending thickness range

| NO. | PLATE MATERIAL | UNIT | MAX. THICKNESS |

| 1. | Stainless steel (SUS) | mm | 1.5 |

| 2. | Carbon steel (MS) | mm | 2.5 |

| 3 | Aluminum (AL) | mm | 3 |

Remarks: The bending toolings can be customized according to the thickness of the user’s sheets.

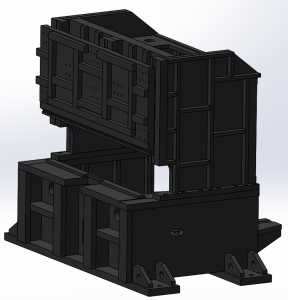

VI.Introduction of bending main body and bending demonstration

- 1.Introduction ofthe bending main body

◆ Servo flexible bending center main body, the main body adopts high-strength welding structure, the main structure structure is stable, and the service life is long.

◆ Heat treatment to remove internal stress, strong rigidity, heavy tonnage, ensure long-term stability of the machine accuracy, and improve the bending accuracy, reliability and durability of the machine.

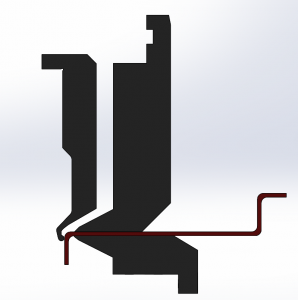

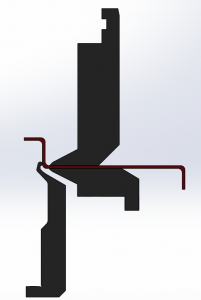

- Bending demonstration

◆Down bending demonstration

◆Upper bending demonstration

- Main parts

Taiwan HIWIN ball screw

Germany Rexroth linear guide

Japan NSK imported bearings

VII.Random documents, random accessories

- Random documents

| NO. | NAME | QTY | REMARK |

| 1. | Equipment packing list | 1 | |

| 2. | Certificate of Compliance | 1 | |

| 3. | User’s manual | 1 | |

| 4. | Electrical schematic diagram | 1 | |

| 5. | CNC system information | 1 |

- random accessories

| NO. | NAME | SPECIFICATION | QTY |

| 1. | Quick-plug air gun | 1 SET | |

| 2. | Allen wrench | S1.5-S10 | 1 SET |

| 3. | Equipment foot pad | 1 SET | |

| 4. | Hose | Ø 8 | 5 METERS |

| 5. | T type tee | Ø 8 | 2 SETS |

| 6. | Nylon cable tie | L200 | 30 LINES |

| 7. | Socket head cap screws | M10*45 12.9 level | 6 SETS |

VIII.User cooperation matters

- Power supply: 3Phase Customized,the voltage fluctuation is -5%~+10%; when the voltage fluctuates greatly, the user must be equipped with a voltage stabilizer, otherwise it will cause the low-voltage electrical appliance to be in an abnormal working state, and the life of the electrical device will be reduced or broken,processing products are scrapped, motor alarms cause stop working, computer hard disk damage and other problems.

- Air source: output above 0.6Mpa, dry and clean compressed air, air supply volume 0.3m3/min; if the air is not dry enough, the user should be equipped with a refrigeration dryer, otherwise there will be water in the pneumatic componentsand thencause the frictional resistance of the piston to increase, also the wear of the sealing ring will cause air leakage and other problems. Especially in winter, it is easy to freeze, leading to aggravated damage to the pneumatic components.

- Ambient temperature: 0°C ~ +40°C; lower than 0°C will cause the oil-water separator, gas tank and other partswith watermay freeze. The lubricating oil will be too viscous due to low temperature, which will affect the lubrication effect, which resulting in damage or failure of components.

- Environmental humidity: relative humidity 20~80%RH (non-condensing).

- Keep away from strong vibration sources and electromagnetic interference; if the distance is too close, users must be equipped with filters, otherwise it will cause computer screen flickering, LED light flickering, driver alarm, encoder abnormality, or interference with other nearby equipment.

- Theenvironment with little dust, no harmful and corrosive gases.

- The foundation is prepared according to the supplier’s foundation plan.

- The user should select personnel who have a high school level or above, understand basic computer operations, and can work in this position for a long time for training.

Reviews

There are no reviews yet.