Panel Bender Manufacturers

Panel Bender Manufacturers

TECHNICAL PROPOSAL

(i)Main Performance Characteristics

1. Machine Performance

The Smart series is a flexible and intelligent panel bender machine designed and produced according to high-precision machine tool standards. It is made of high-specification castings, and both the cast and welded parts are subjected to strict stress relief processing. High-precision machine tools are used for integrated processing, ensuring long- term accuracy, stability, and high rigidity during operation.

2. Axis Configuration Description

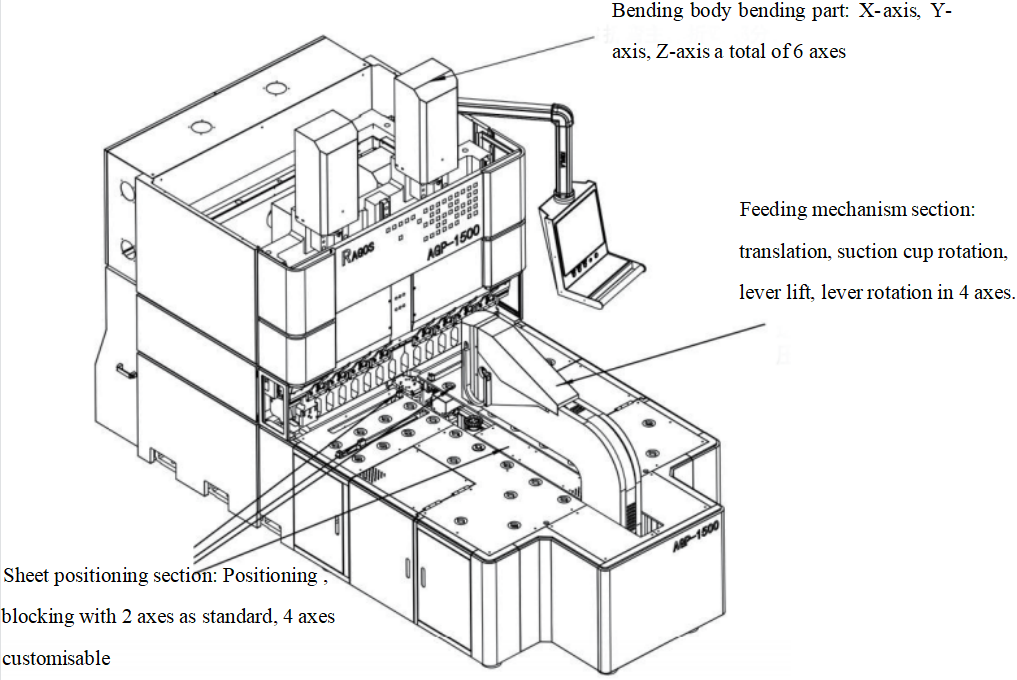

The machine is equipped with a total of 8 axes, including 3 axes for the bending main body (X, Y and Z axes), and 3 axes for the feeding mechanism (translation, pallet lifting, and pallet rotation). The plate positioning part includes 2 axes for positioning and part blocking.

3. CNC Control System

(II)Main Bending Process

1. Bending Process Description

Bending Process Requirements:

1 . The surface of the material to be bent cannot have downward protrusions, as this may cause

interference with the workbench and prevent automatic bending.

2. For suction cup bending centers, when bending all four sides of the material, there should not be

large openings in the center of the material, as this will prevent the suction cups from holding the

material in the center. For pressing rod bending centers, there should be a space reserved for

pressing the material .

3. . The distance from the edge of the hole to the bending edge should be ≥ 5mm . Otherwise, there may

be a pulling effect after bending (the larger the thickness of the material, the larger this dimension should

be).

4. . After forming, the bending direction can only be bent in one direction,

ultimately facing downward.

5. . Whether the bending center can bend automatically depends on the bending

process and sequence of the part. The final decision will be based on the

approved drawing .

6. . The dimensions of the bending tools in the figure on the right are standard,

and can be customized according to customer requirements .

7. . The figure above shows some examples of upper and lower bending . The actual dimensions

will be based on the size of the product.

2. Basic Bending Dimension Requirements for Some Parts

3. Diagram of partial reverse direction bending requirements

4. Requirements for the use of partial hinge knives

5. Special bending processes

Note: Special bending processes may result in inconsistent deformation compared to regular bending processes. It is necessary to verify whether the actual process can meet the product requirements.

(iii)Bending Size Range

1. Minimum range of bending edge sizes for the AG series

| Plate thickness(mm) | 0.3~0.6 | 0.7~1.0 | 1.1~1.2 | 1.3~1.5 | 1.6~2.0 |

|---|---|---|---|---|---|

| Minimum Size(mm) | 4 | 5 | 6 | 8 | 10 |

2. Tolerance Range for Bending Size and Angle in AG Series

| Length(mm) | 300~500 | 501~800 | 801~1000 | 1001~1200 | 1201~1500 | 1501~1800 | 1801~2000 | 2001~2500 |

|---|---|---|---|---|---|---|---|---|

| Dimensional tolerane at both ends(mm) | ±0. 1 | ±0. 1 | ±0. 1 | ±0. 1 | ±0. 15 | ±0.25 | ±0.25 | ±0.25 |

| Angular tolerance(°) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.75 | ±0.75 | ±0.75 |

| Diagonal tolerance (mm) | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ±0.75 | ±0.75 | ±0. 1 | ±0. 1 |

(iv)Main technical parameters

| Name | Unit | AG-2000 (suction cup) |

|---|---|---|

| Bending length | mm | 2000 |

| Sheet length | mm | 2100 |

| Sheet width | mm | 1250 |

| Bending height | mm | 170 |

| Total bending length | mm | 200 |

| Minimum formed internal dimensions on all four sides | mm | 360×180 |

| Double-sided minimum formed internal dimensions | mm | 180 |

| Minimum radius of circle | mm | 1.2 |

| Fastest continuous bending speed | s | 0.5/Knife |

| Distance between upper and lower knives | mm | 180 |

| Bending angle | ° | 0-360° |

| Maximum material thickness | mm |

Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 |

| CNC control system | Cell | Star300-LGx |

| Operating systems | OS | Win7+OS |

| Number of axes | axes |

13 axis as standard; 14 axis customised |

| Machine dimensions | L | mm | 4580 |

| W | mm | 2400 | |

| H | mm | 2950 | |

| Machine weight | kg | 13800 | |

| Total power | KW |

44.65/45.05 |

|

(IV) Main Advantages

Cast body (stable structure, not easy to deformation, high precision)

Nitrogen counterweight (10 times longer screw life)

Independent vacuum pump (strong adsorption force, higher precision)

Independent air conditioning (strong heat dissipation and stability)

(vi) Random information, random attachments

| Name | Quantity | Remarks |

|---|---|---|

| Toolbox | One set | |

| Bottom foot cushion foot | One set | |

| Foot switches | One set | |

| Power cord |

(vii) Machine site installation requirements

1. Hydraulic oil: imported VG46# anti-wear hydraulic oil.

2. Power supply: 380V50HZ, voltage fluctuation of 10% – 5%

3. Ambient temperature: 0oC- +40oC

4. Ambient humidity: 20-80%RH relative humidity (non- condensing)

5. far from strong vibration sources and electromagnetic interference

6. dust-free and free from harmful and corrosive gases

7. the foundation should be prepared according to the foundation plan of the supplier

8. the user should be trained to use the machine.

Quality inspection

1. Cleaning and inspection of parts before assembly, including racks, molds, work surfaces, etc. Ultrasonic cleaning is used, and the hardness of the mold is tested, and important parts are performed three-coordinate inspection.

2.During assembly, professional and technical personnel will assemble and clean each part and apply butter. Lubrication, precise installation in accordance with advanced procedures, and dial gauge adjustment to that all components are installed properly.

3. After the assembly is completed, perform processing tests on the machine in accordance with the process requirements to ensure the action of the machine is complete and there is no abnormal noise.

4. After the test run, the machine shall be further debugged and inspected, and the electric power of the machine shall be checked the operation of the device and the system and adjust the system parameters. For upper and lower knives, workbenches, suction final commissioning and accuracy testing of the pan, positioning system and oil circuit system.

After–sales and technical services

Here is a possible revision to improve the clarity and readability of the provided text:

1. The supplier will provide drawings for the equipment foundation, and the demander will be responsible for the actual construction.

2. Once the products are assembled in the supplier’s factory, the demand side will be promptly informed of the specific delivery time and any preparatory work necessary for installation.

3. The supplier is responsible for commissioning the equipment on the demand – side use site, provided that the demand side cooperates and provides the necessary conditions, including the installation of required lifting equipment, hydraulic oil, electricity, and any other necessary components.

4. During the installation and commissioning of the equipment on the demand side, the supplier will provide free online training and technical consulting services to the relevant technical personnel . If on – site training is required, the cost will be USD 200 per day.

5. After the installation and commissioning process, both parties will jointly accept the technical agreement and relevant technical annexes that have been signed.

6. The supplier provides a one -year quality assurance period from the issuance of goods. During the warranty period, any damage to the parts caused by reasons other than user error will be replaced free of charge (wearing parts are not covered by the warranty) . After the warranty period expires, the supplier will implement a lifetime warranty, with the cost of work charged.

7. The supplier offers online service support for the demand side . Upon receiving a quality report from the demander, the supplier will respond within 4 hours and provide a solution within 24 hours.

Warranty

1. Warranty period:

The warranty period is 12 months after installation and commissioning. Alternatively, a 24 -month warranty period option is available.

2. Warranty scope:

A. During the warranty period, any malfunction of the machine during normal operation will be repaired free of charge .

B. Any parts damaged during normal operation will be repaired or replaced free of charge .

3. Exclusions from warranty coverage: The warranty does not cover the following:

A. Any damage caused by human factors .

B. Any attempt to repair the machine by anyone other than authorized personnel without prior consent .

C. Any damage caused by force majeure events, such as war, fire, typhoon, flood, or earthquake .

About the author

Alvis Zhang of VISTMAC Machinery

VISTMAC is a professional manufacturer and exporter in tube processing machines, includes Pipe Bending Machines, Pipe Cutting Machines, Wire Bending Machines, and Pipe-End Forming Machines Series.

Let’s Talk

China CNC Pipe Bending Machine Manufacturer directly selling Pipe Bending Machine, Wire Bending Machine with CE marking at affordable price

© Copyright 2023. All rights reserved.

Phone/WeChat: +86-13771480707

Email: sales@chinasmartcnc.com

Address: Head Office: No.77 Huicheng Road, Huishan District, Wuxi, Jiangsu, 214151, ChinaWORKING DAYS/HOURS:Mon-Sat / 8:00 AM – 18:00 PM

About us

Machines

Showroom

Support

News

Contact us

Help & FAQ

News

Privacy Policy